OUR VISION

At BEEP Mobility, we live our vision with carefully planned product development, in-house production, high quality standards and flexible logistics solutions. This enables us to execute at a high level and allows us to provide value to every customer with products that have a price-performance ratio that is in line with the market.

BEEP Mobility, in the spirit of a future and growth-oriented young company, proactively accepts its responsibility for sustainability and prioritises an attention to society and the environment. Contemporary leadership, new work methods and a hands-on mentality are important components of our company philosophy.

Our company is driven by a passion that keeps us at the forefront of developing novel and innovative solutions in a collaborative approach with our customers and partners - TOGETHER WE MOVE FORWARD.

OUR TEAM

Our team is characterized by a wide range of industry, product, and specialist experience. High qualifications in engineering, adhesive and welding technology, a broad knowledge of production methods and surface technology, as well as skilled project management and process orientation, are among the core competencies of our employees.

Additionally, our employees regularly participate in training and continuing education events in order to be able to maintain this high level of knowledge and continue to be informed of the state-of-the-art technology that can be offered in our core market segments.

ONLY WHEN EVERYONE KNOWS THE GOAL,

THE DIRECTION IS RIGHT.

PRODUCTS AND SERVICES

BEEP Mobility realizes projects in the field of interior components for rail vehicles and in the field of mechanical engineering. Our services offer facilitating development and scaling parts into production, complete assembly of whole systems, as well as establishing associated logistics concepts. Additionally, we also take on individual, unique assembly or services when applicable.

CERTIFICATION

TO SUCCEED

YOU HAVE TO BE DIFFERENT.

Ted Turner

OUR CustomerS

We focus on the customer.

PARTNERS

With us, partnership knows no boundaries. We develop the solution for every individual requirement and incorporate the latest findings and developments from our partners and suppliers. In this way, we can meet every individual customer request in full.

CAREER

Our strength is our employees.

We are looking for proactive individuals who make a difference and who dare to bring bold, innovative ideas to our company. In return, we offer exciting employment opportunities in all areas, a significant amount of personal accountability, a diverse range of responsibilities at every career level, and a familial environment in, and for, a young, dynamic team.

#Together we move forward - NEW WORK @ BEEP Mobility

Produktions-/Montage-Mitarbeiter*in (38,5 h/Woche)

You still want to meet us and shape your future with us?

Send us your initiative application. We are looking forward to get in touch with you.

Contact

BEEP Mobility GmbH

Dieselstraße 5

3362 Mauer bei Amstetten

+43 7472 930 82

office@beep-mobility.at

NEWS

2024

September 2024

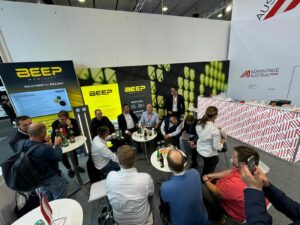

Innotrans - The future of mobility

It wasn't just our stand that was very well attended. Our products in the vehicles attracted great interest.

Ceiling systems and luggage racks were admired in the Stadler RS Zero and Stadler Citylink vehicles.

2023

December 2023

Merry Christmas & a Happy New Year

September 2023

We celebrate!

Several reasons gave us the idea to organize a celebration.

We were able to welcome around 60 invited guests, including employees, partners, suppliers, customers, family and friends at #BEEP Mobility.

Our guests take advantage of the opportunity to tour the company and network before we review the first two years of our existence.

The founding phase during Corona Lockdown - the first order - BEEP goes US - Innotrans 2022 - Move to Dieselstrasse 5 - our product portfolio, further BEEP insights, ... were presented to the guests in short stories and with images.

Current figures and facts, our lived vision #togetherwemoveforward and the outlook for upcoming tasks, challenges and goals were perceived as very impressive.

It’s amazing what you’ve already created. We didn’t even know that!” said a family member.

“Do you all wear your BEEP shirts when you sleep or just at work?”, one of our friends.

“With pleasure, always for you,” a supplier interjected.

“You do that too? Can you please come by on Monday!”, a satisfied customer.

We then ended the evening comfortably together and we will remember it as a #beepastic celebration.

Now get back to work, then nothing will stand in the way of repeating it.

April 2023

World first sound insulation!

You never heard about the SHERPA Sonus-Connector ? We're not surprised, but this should change.

This is one of the latest products from Sherpa Connection Systems GmbH, which is revolutionizing connection technology in timber construction, a world first.

During its development, we made our contribution with our know-how for the right bonding. But we are also responsible for the final production, quality assurance and packaging. Packed in boxes, it is ready for delivery to the end customer.

Apart from our primary field of activity in the rail vehicle industry, we also support and supply customers from other industries with high-quality products.

#soundinsulation #timberwork #revolution

February 2023

We moved!

We moved with our headquarters to Dieselstraße 5, 3362 Mauer bei Amstetten. (opposite our previous headquarters)

Feel free to visit us in our new office & production areas.

Certifications!

We have successfully completed all our certifications also at our new headquarters. Welding acc. to DIN EN 15085-CL1. Bonding acc. to DIN 6701-A1 and DIN 2304 S1.

We are the exclusive EU-wide sales representative for Train Tube LED

TrainTubeLED develops fully compliant LED tubes for the railroad industry.

Fluorescent tubes will be banned in the railroad industry in 2023. BEEP Mobility is happy to support you in planning and managing your refurbishment project. For more information, please visit: Train | Train Tube Leds or feel free to contact us at - office@beep-mobility.at.